Deutsche Bahn is investing over EUR 400 million in the new ICE maintenance depot in Dortmund and creating up to five hundred new jobs. The Cologne-Nippes ICE depot will serve as a model for the new depot.

Contact

DB Engineering & Consulting

EUREF-Campus 14

10829 Berlin

Germany

The new ICE maintenance depot in Dortmund is expected to start operations in 2027. A tight schedule indeed, but one that architect Miriam Kiesel believes is feasible. As project manager at DB Engineering & Consulting (DB E&C), the architect is working flat out with the design team – comprising designers from Regions North, East, South and West – to meet the deadline. MS Teams meetings help to speed up work between team members from the various regions.

In her role as project manager for the new maintenance depot at the Port of Dortmund, Miriam Kiesel’s first job is to collaborate closely with the client, DB Fernverkehr, on requirements planning and the project requirements specification. She is also tasked with organizing the design work and ensuring that all parties involved can work together. “I collect the planning specifications and, together with my management team, coordinate the designers on the design team. I also keep the information flowing, assign tasks and invite small teams to clarify outstanding issues quickly and directly,” she says. I ask whether this is her first project for Deutsche Bahn. “No,” she replies. Miriam Kiesel started working at DB E&C in May 2021 and helped to design the new maintenance depot in Cottbus. That experience has stood her in good stead in her current role – as has her previous job at a construction company, where she helped to plan and implement construction projects in the depots of a rail vehicle manufacturer.

Getting an agile project over the line quickly

When it comes to designing the new depot, speed is of the essence. In November 2021, Miriam Kiesel traveled to Dortmund for the first time to find out more about the major project. And the construction expert was extremely impressed. She found the idea of managing a highly agile project right from the start very appealing. “And managing it in such a way that we get the results we want as quickly as possible,” she explains.

The contract signed by DB Fernverkehr arrived at DB E&C in December – just five weeks after the initial discussions. The challenge was to have a complete planning approval process in place for the new depot in ten months. The team is using a feasibility study by Schüßler-Plan as a foundation. “We have a rough track layout that we need to refine as quickly as possible and agree with the customer as a working basis,” says Kiesel. Before designing the building, the as-built documents – and the drawings of the ICE depot in Cologne-Nippes – were collected and examined. “To ensure that we can keep to the tight schedule, DB Fernverkehr wants us to base the design for the Dortmund ice depot as closely as possible on that of the Cologne depot, which was also designed by DB E&C,” she says.

Made to measure

During the course of the project, however, it has become clear that Dortmund cannot be a 100% replica of Cologne. Some changes to the Cologne model and original track layout have been requested for the new depot. This is placing the design team under pressure as the deadline for submitting the application for planning approval still has to be met at all costs.

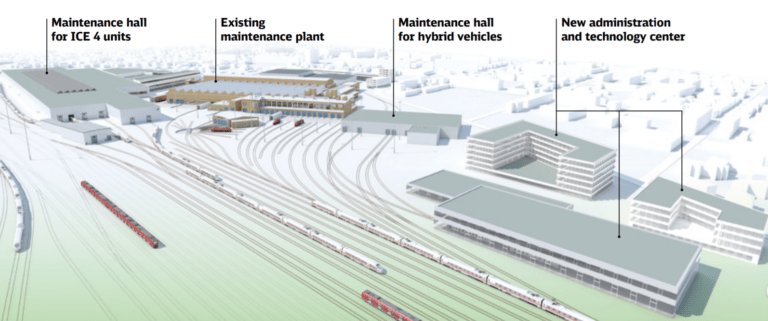

Site of the new ICE depot in Dortmund

Site of the new ICE depot in DortmundSite of the new ICE depot in Dortmund  The ICE 4 class 412 at the ICE depot in Cologne-Nippes. Up to 17 trains a day will be maintained at the depot near the Port of Dortmund.

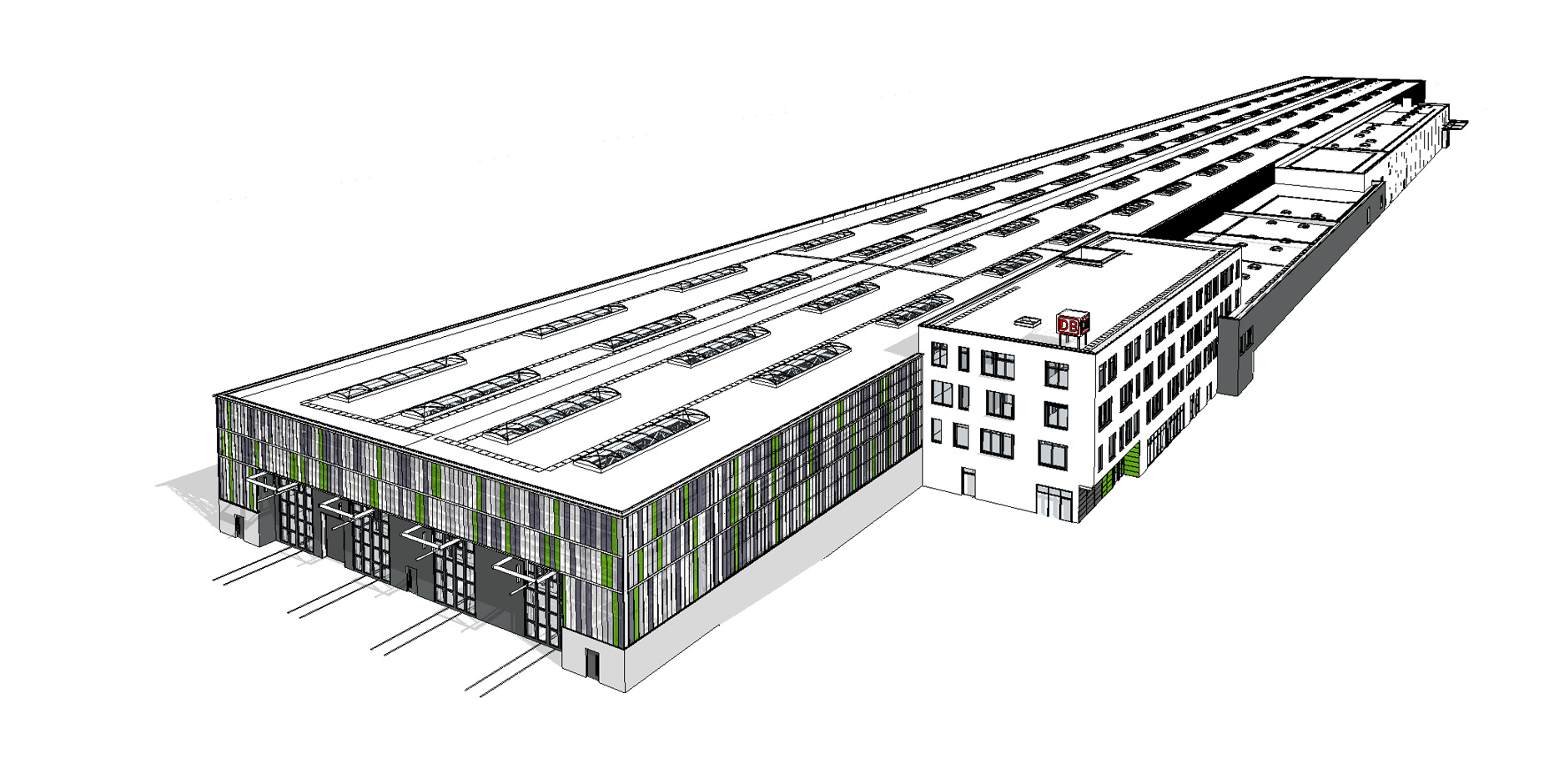

The ICE 4 class 412 at the ICE depot in Cologne-Nippes. Up to 17 trains a day will be maintained at the depot near the Port of Dortmund.The ICE 4 class 412 at the ICE depot in Cologne-Nippes. Up to 17 trains a day will be maintained at the depot near the Port of Dortmund.  Model graphic of the new ICE depot Dortmund

Model graphic of the new ICE depot DortmundModel graphic of the new ICE depot Dortmund

In particular, reaching final agreement on operational processes and PME specifications is proving to be a challenge. However, Ms. Kiesel doesn’t let this time pressure detract from her enjoyment of the job: “There are different requirements for each train type and for each ICE class. I find it exciting to bring all these specifications together to create the most flexible depot possible.”

Following a design freeze of the site layout and building volumes in April, the technical design is currently being worked out by the entire discipline team. The list of tasks is long. It includes, among other things, developing static energy concepts, determining the track layout and assessing the structural analysis of the maintenance shed. “Hopefully, we’ll have agreed on a design by early June,” says Kiesel. Other milestones include final design by Spring 2023, construction drawings by the end of 2024 and the start of construction in early 2025. Can all of this be achieved? “Yes,” says Ms. Kiesel, adding that the collaboration with DB Fernverkehr is going very well.

The ICE depot near the Port of Dortmund

The new ICE maintenance depot in Dortmund is being built to the west of the city’s port on the site of a derelict yard. The facility, which includes a 450-meter-long maintenance shed and four tracks, will have capacity from 2027 to make up to seventeen ICE trains a day fit for the rail again. DB Fernverkehr’s eleventh maintenance depot will be one hundred percent carbon neutral and supplied by renewable energy sources, using a solar thermal system for heating and hot water, for example. Automation as well as intelligent building systems engineering and facility control will minimize energy consumption. Deutsche Bahn is investing over EUR 400 million in the depot and creating up to five hundred new jobs in Dortmund.