Digital Twin Pilot

Modern rail operations today face a multitude of complex challenges: An aging infrastructure, increasing demand and the ever more urgent need for greater efficiency characterize everyday life. What is particularly problematic is that an uncoordinated approach to asset management further intensifies these challenges. It leads to operational inefficiency, higher maintenance costs and frequent system failures. Digital twins represent a promising solution by offering a structured and precise method of mapping the railroad’s operating processes, thereby enabling a targeted approach to addressing the aforementioned issues.

A look at the various maintenance strategies clearly shows that predictive maintenance is the most innovative and effective approach. It is supported by digital twins and makes it possible to detect potential failures before they occur. This can significantly reduce downtime and avoid unnecessary repairs. Digital twins use data from sensors, maintenance histories and analytics to accurately predict asset management. The result is fewer breakdowns and a significantly longer service life for the infrastructure.

In Colombia, DB Engineering & Consulting provides an outstanding example of the success of this approach with a pilot project in the country’s first metro system, which has been in operation for 25 years. Between November 2023 and April 2024, we worked on the implementation of digital twins here. The project start phase involved detailed coordination of objectives and strategies as well as comprehensive knowledge transfer and training. Furthermore, the project was phased, starting with an assessment of existing data to determine the need for additional surveys or maintenance information. A metro substation was chosen as the pilot for its well-documented operations and maintenance (O&M) information. The focus was on three key aspects: analyzing the available operations and maintenance (O&M) data, determining the appropriate level of detail (LOD) and level of information (LOI) for the building information modeling strategy, and defining the desired outcomes.

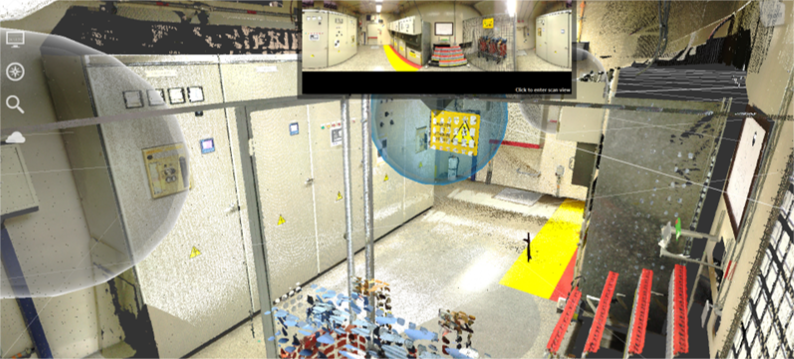

In addition, the existing maintenance processes were characterized by inefficiencies, which were now to be remedied by integrating the digital twins. On-site scans and photos were taken and a point cloud was created to develop a BIM model. This model was integrated with Autodesk Tandem and synchronized with SAP to enable seamless real-time data exchange and IoT data capture. Moreover, close collaboration was undertaken with the project stakeholders with a view to the compilation of all documentation related to architecture, electrical systems and maintenance requirements.

Following the implementation of the digital twins, maintenance processes have been significantly optimized. By integrating real-time data, asset managers can now make faster and more informed decisions, communication is improved and maintenance tasks can be coordinated more effectively. Predictive maintenance, supported by the digital twin pilot, is a forward-looking approach that not only reduces costs and downtime, but also paves the way for a more efficient and reliable rail system.

Project data

- Pilot project: Colombia’s first metro system

- Project phases

- Strategy and pilot evaluation

- Understanding the existing management process

- Data collection

- Modeling

- Connection and integration

Scope of services

- Awareness and knowledge transfer

- Fundamentals of BIM and Digital Twins for Asset Management

- Implementation of BIM Pilot for Asset Management

- Critical asset definition

- BIM Strategy for Asset Management development

- Creation of a digital twin

- Data acquisition: Point cloud

- BIM modelling: Scan to BIM

- Data connection: Interactive display and O&M data connection (Autodesk Tandem, SAP, IoT)