VDE 8.1 – New Ebensfeld-Erfurt line

The German Unity Transport Projects (VDE) are considered to be groundbreaking in terms of the modernization and unification of German rail transport infrastructure. Within this framework, the VDE 8 is undoubtedly the largest rail project. It comprises new construction and upgrades of line sections linking the cities of Nuremberg, Erfurt, Halle (Saale), Leipzig, and Berlin, measuring over 500 kilometers in total.

A key element of VDE 8 is the new Ebensfeld–Erfurt line (VDE 8.1), built over a length of 107 kilometers. This section underwent double-track electrification and was upgraded for maximum speeds of up to 300 kilometers per hour.

Upon commissioning in 2017, travel times in regional and long-distance traffic on the route between Bavaria and Thuringia were optimized and ultimately shortened. As a result, the Ebensfeld–Erfurt line section makes a significant contribution to the efficient handling of passenger and freight transport throughout Europe.

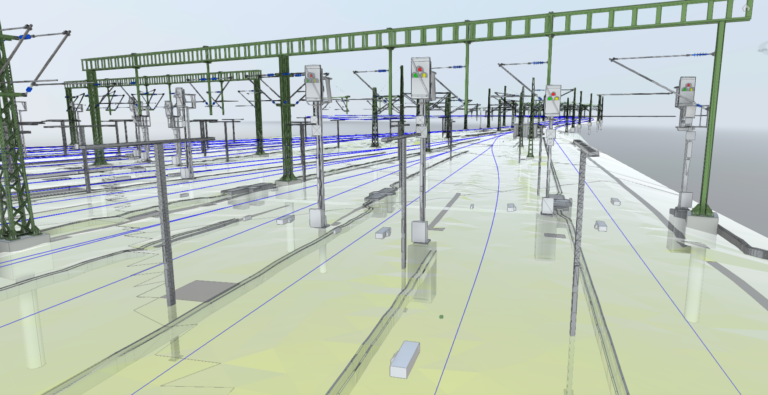

The route is characterized by the use of advanced construction methods, such as concrete slab track according to the Bögl and ÖBB Porr systems and the use of ballasted track in the passing sidings. Furthermore, the ETCS – Level 2 standardized European train control system and high-performance overhead lines were deployed, providing just two examples that illustrate the technological complexity of the construction project.

Unique features include the record-breaking structures along the route, such as the Blessberg Tunnel and the Ilm Valley Bridge. These account for over half of the line section and set new standards for new-build lines in Germany.

Particular priority was given to the safety of the system, including consideration of measures in the event of damage. Emergency grounding in the tunnels was ensured by installing 14 overhead line voltage test devices in the tunnels.

The new-build line runs through a large number of tunnels and crosses a lot of bridges, which not only overcome the topographical challenges in the region but also ensure an efficient link between the towns involved. In total, the route runs through 22 tunnels with a total length of 41 kilometers and also crosses 29 viaducts with a length of 12 kilometers.

The route begins in Ebensfeld and initially runs for around 34 kilometers through the Main plain on Bavarian territory before passing Coburg to the east. Interestingly, the line does not merely pass by the town but also links it directly to the new-build line via two connecting curves at Niederfüllbach and Dörfles-Esbach. This helps to strengthen the regional transport infrastructure.

The line section then reaches the Theuern passing station northwest of Grümpen, where the Blessberg tunnel begins. This stretches over a length of around 8.3 kilometers and crosses the Blessberg with an altitude of 862 meters as well as the Rennsteig near the Pechleite with an altitude of 838.5 meters. The highest point of this line section is at Goldisthal, where bridges over deeply incised valleys alternate with tunnels. Here the Silberberg Tunnel stretches over around 7.4 kilometers and crosses Grossbreitenbach and the protected Upper Möhrenbach Valley. A bridge measuring 1,681 meters in length spans the Ilm Valley between Langewiesen and Gehren and forms an important link between the affected communities. The new-build line and the A71 highway then cross at Trassdorf and run parallel for around 23 kilometers.

Between the Erfurt districts of Bischleben and Hochheim, the new-build track meets the existing Bebra–Erfurt line, which serves as the western entrance to the state capital. Two additional new-build tracks will be added to this section to meet growing transport requirements.

Project data

- VDE 8.1 – Ebensfeld-Erfurt new-build line

- 107 km of trackwork (TEN HSR)

- Of which 32 km of concrete slab track built in accordance with the Max Bögl system

- Of which 75km of concrete slab track built in accordance with the ÖBB Porr system

- Ballast, custom design, cemented ballast

- 22 tunnels with a total length of 41 km

- 29 bridges

- 48 noise control structures

- Power supply systems

- 300 km of overhead line equipment

- 14 overhead line voltage test devices

- Infrastructure: hot box detector

- Technical equipment, electrical power system

- Transformer stations, emergency power systems, switch heating systems, grids, tunnel safety lighting

- Tunnel equipment

- Rolling pallets, air lock doors, standpipes, handrails

- Rescue areas

- Underground cable installation away from the route, foundation and positioning of concrete switchgear building, expansion of rescue areas

- Environmental remediation/waste/wastewater

- Technical waste inspection

- Measurement of stability and deformation, laboratory testing, geotechnical construction supervision

- New-build line

- Permanent way: concrete slab track

- Length of line: 107 km

- Design speed: 300 km/h

Scope of services

- Construction Management and Supervision

- Construction implementation planning

- Structural engineering

- Overhead line and electrical power systems

- Overhead line voltage test devices and telecontrol systems

- Design coordination and review

- Construction management

- Construction site management

- Cost and schedule management

- Environmental and Geoservices

- Monitoring through surveying

- Stability and deformation measurement, laboratory testing, geotechnical construction supervision

- Occupational health and safety coordination

- Invoicing and claims management

- Outstanding performance and defect tracking after commissioning

- Coordination of warranty defect rectification