Coal is on its way out, and rail is on its way in. Deutsche Bahn’s new large, modern and environmentally friendly maintenance depot will create hundreds of new jobs in the Lusatia region in the long term.

Germany is phasing out coal-based power generation by 2038. That is good for climate protection, and Deutsche Bahn is playing a very specific role in shaping this structural change. Deutsche Bahn’s Member of the Management Board for Infrastructure Ronald Pofalla and Sabina Jeschke, his colleague and Member of the Management Board for Digitalization and Technology, presented plans for the new environmentally friendly maintenance depot in Cottbus and additional multi-billion-euro infrastructure projects for Lusatia on September 17.

“The examples in Brandenburg and Saxony illustrate the historic dimension of the structural change and the railroad’s role as an important factor especially clearly: in Cottbus, we are going to create the most modern maintenance depot in Europe and around 1,200 new jobs. And we are going to expand all the main railway routes in Lusatia. This will mean more and faster connections from the region in all directions: to the German metropolitan areas as well as nearby Poland,” Pofalla said, hinting at the tasks our designers and construction supervisors will face in the years to come.

Planning is already in full swing

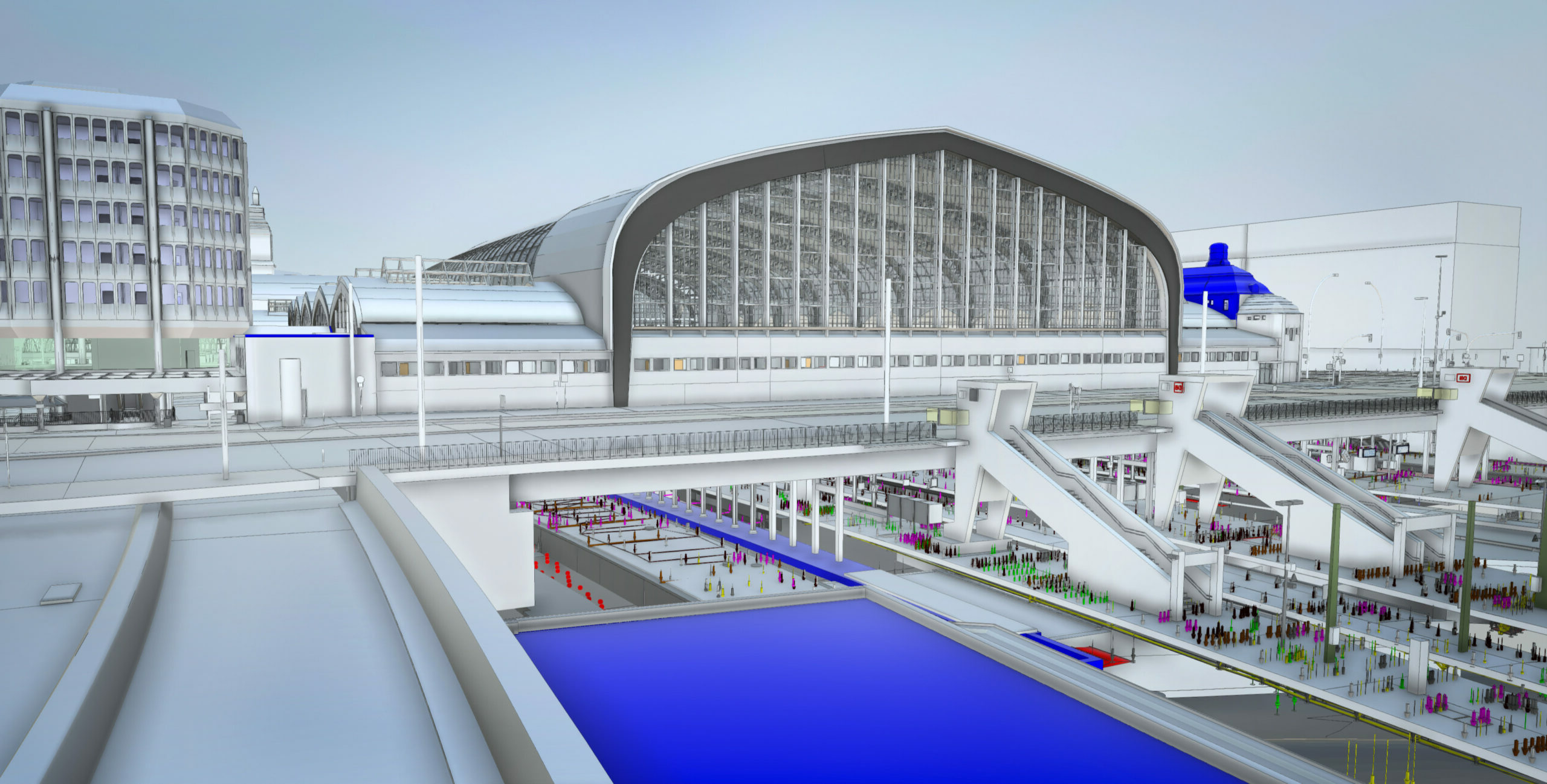

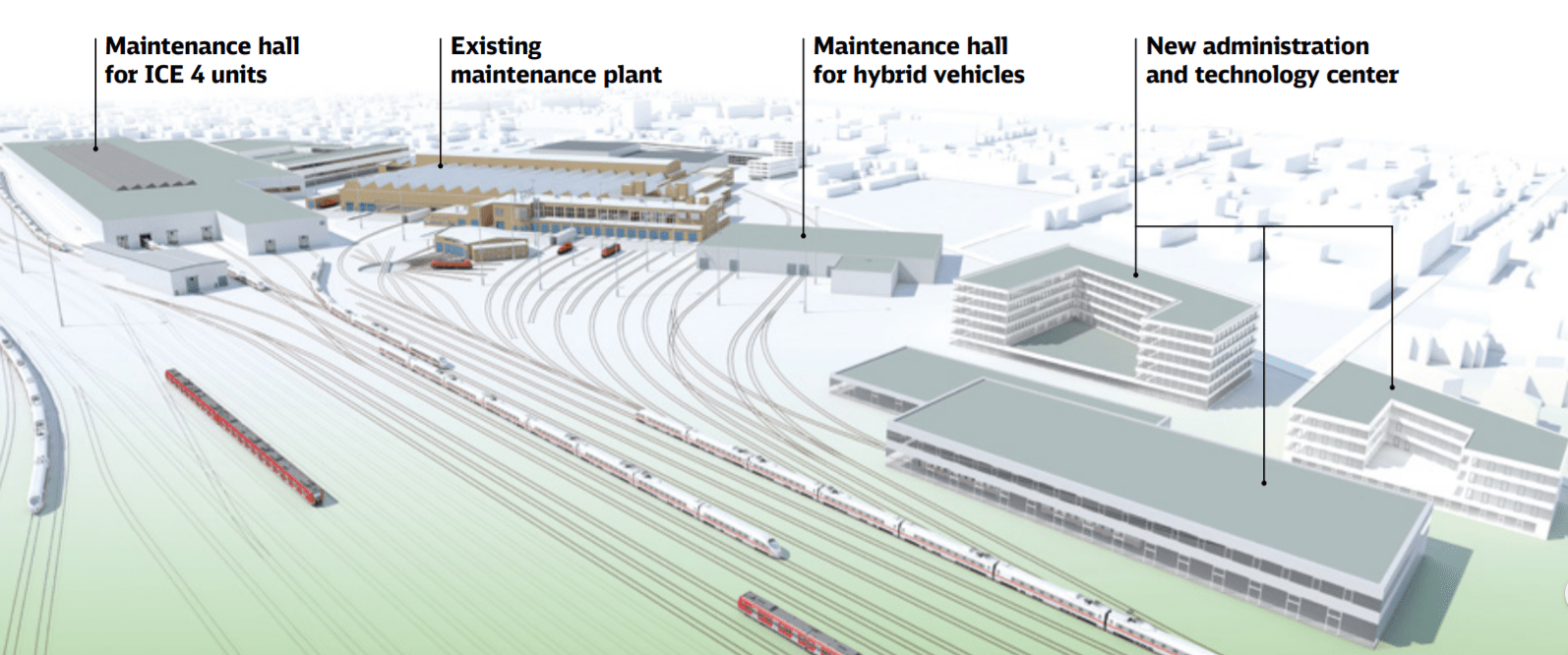

The new depot in Cottbus will use artificial intelligence, sensor technology, and robots that cooperate and communicate with employees to revolutionize existing processes, which will raise ICE maintenance capacities to a new level. After all, raising capacity is the only way to achieve the integrated regular-interval timetable for Germany, which aims to connect German’s major cities at half-hour intervals in the future. The Cottbus depot is where heavy maintenance is performed on electric railcars and where ICE trains are serviced, repaired and modernized. The depot will also be the only one in Germany to perform maintenance on hybrid vehicles. The DB Center for Hybrid Research will move into the administration and technology center, as will a training and service center with training workshops.

DB Engineering & Consulting enjoys a good reputation in facility planning thanks its many projects. It most recently served as the overall design coordinator for the Cologne-Nippes ICE facility. This good reputation was confirmed by the fact that the feasibility study, basic evaluation and preliminary design for the Cottbus depot were awarded to the experienced design team headed by project manager Rüdiger Almeroth at our Berlin office. Later design stages beginning with final design (HOAI phase 3) will be carried out through an alliance with the project owner from DB Fahrzeuginstandhaltung GmbH (FZI).

“The heart of the project is the maintenance shed for ICE 4 and other types of multiple units; it is 522 m long and 100 m wide,” Almeroth said. “In addition, both the necessary workshops and warehouses and the required infrastructure for tracks and roads are being designed. We are designing the project entirely using the BIM method. We are pursuing the “two-shed concept” in the current phase, which will allow us to move up the first maintenance work on ICE 4 trains by two years. One shed with two maintenance tracks will be built and go into operation by 2024. The second, larger shed with four maintenance tracks, a paint line and the entire outdoor facility will be built later.“

Discover how we design depots:

Environmentally friendly and innovative: energy solution for the green depot

Plans call for an innovative energy solution to be implemented for the new green depot. In addition to photovoltaics, geothermal and hydrogen were also considered as sources of power for the depot. The depot will require a large amount of power, which will come from green energy generated by the local utility company, Stadtwerke Cottbus. The buildings will have retention roofs,* allowing rainwater to be collected, stored and reused in the event of a fire. Building automation featuring a smart grid and infrastructure logistics for the depot are a high priority.

A multicopter survey of the future construction site and the existing buildings was used to create a flight overview on the web interface Pix4D BIM so the data provisioned could be displayed and used more easily. “It is possible to switch among the different flight sections within the web interface. In the application, markers can be set in the point cloud and in the orthomosaic featuring a stored elevation model (DOM); distances, areas, and volumes can be measured; and cross-sections of the profile can be easily created, divided, and checked,” said Philipp Knötzsch from our Dresden office, explaining the advantages of Pix4D BIM.

All preliminary design work for all five FZI subprojects and the DB Netz portion were compiled and delivered on time in April, marking the end of HOAI phase 2. The project is currently in the design-to-cost phase, and we are reviewing cost-optimized solutions.

* Retention roofs are green roofs whose purpose is to retain water, delay runoff, improve the climate, create a cooling effect, and minimize emissions from underlying building surfaces.

Contact

Sarah Geißler

Marketing & Communications

EUREF-Campus 14

Torgauer Strasse 12-15

10829 Berlin

Germany