Modernization of the Berlin Ostbahnhof traffic station under rolling wheels

Berlin Ostbahnhof is the third largest railroad station in Berlin, making it one of the most important transport hubs in the German capital. The heavily frequented station is currently being modernized to meet to the latest construction and safety standards. The project is divided into two separate construction phases.

The first stage of modernizing Berlin Ostbahnhof lasted two-years and was successfully completed in 2012. It included glazing the north façade, renewing the drainage system and renovating the steel frames of both hall roofs (columns and beams) including the application of corrosion inhibitor and a fire-resistant coating. This construction phase also covered renewing the tie rods and replacing the lighting and PA systems on the platforms.

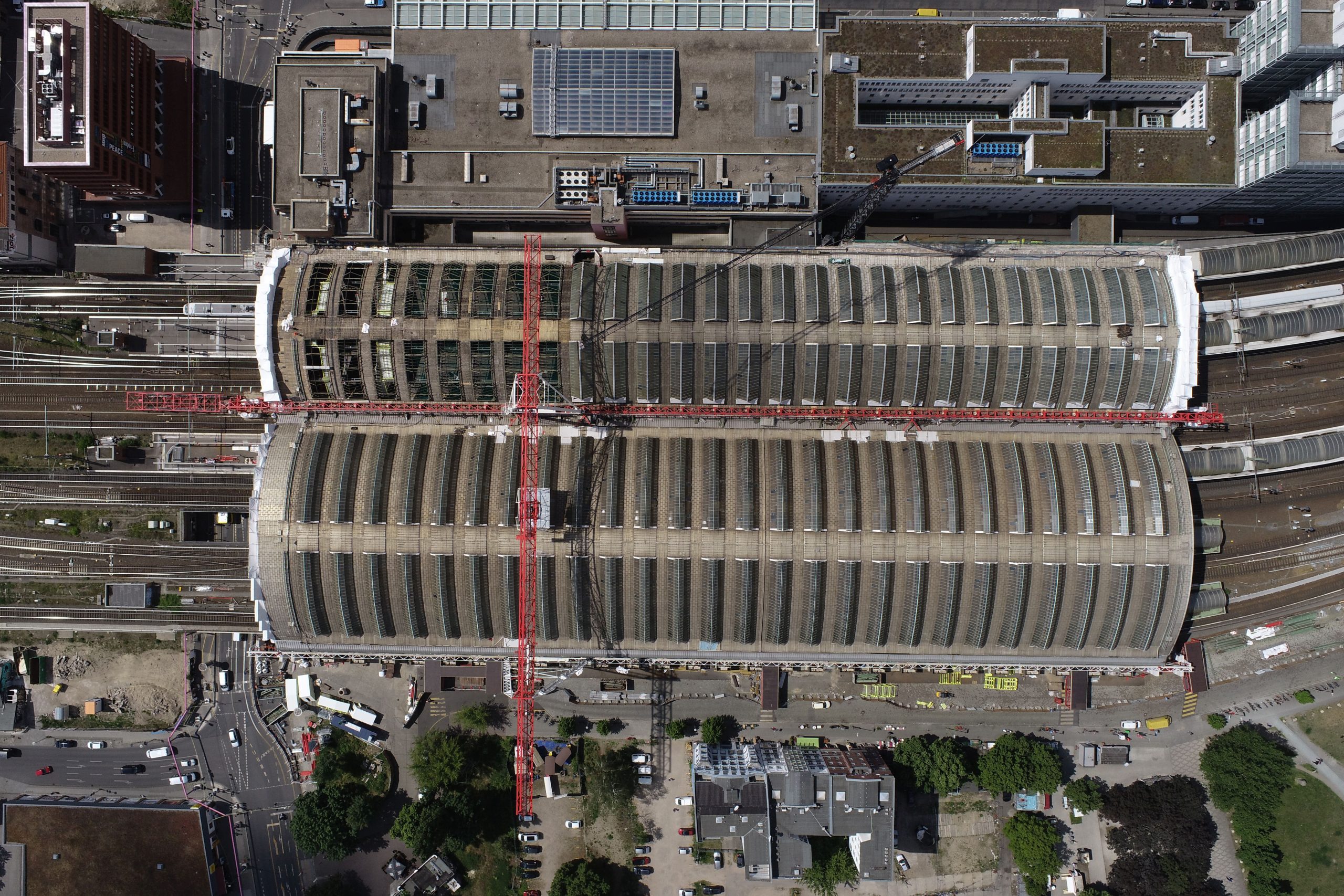

Work on the second construction phase has been underway since October 2021, focusing primarily on replacing the 100-year-old roof coverings in the north and south halls. These roofs are being covered with a new multi-layered roof structure with a load-bearing trapezoidal profile sheet and are also being fitted with a glass structure. This work also encompasses repairing the existing frame ties and renewing the steel structure of the skylights, purlins and wind braces including the vertical tension rods as well as the guide rails and access systems.

A protective bridge with integrated lifting gear was constructed so that construction work can be carried out while the building is in service. This structure extends over both roofs of the track halls. This innovative engineering design is unique and was developed exclusively for this construction project. It means that building materials delivered to the site can be easily transported above the tracks while they are still in use. This measure will allow the modernization work to proceed smoothly without significantly impacting the approximately 100,000 people who pass through Berlin Ostbahnhof on a daily basis.

Project data

- Extensive modernization work in two construction phases up to 2025

- New roof covering in north and south hall

- North hall: approx. 210 m long, 55 m wide and 20 m high

- South hall: approx. 210 m long, 40 m wide and 18 m high

- Overhaul of the frame ties

- Renewal of the wind braces including the vertical tension rods

- Renewal of the steel purlins

- Renewal of the skylights as a standard detail roof system

- Renwal of the roof covering as a standard roof system

- Renewal of the gable facades

- Construction of the internal and external access systems

- Installation of a lightning protection system

- Protective bridge with integrated lifting gear

Scope of services

- Construction supervision

- Superstructure / structural engineering (SE)

- Control-command and signaling

- Electrical engineering

- Corrosion protection monitoring

- Construction implementation planning

- Construction management

- Implementation manager

- Drawing release management

- Schedule control

- Compilation of commissioning documents with DB E&C’s in-house commissioning tool

- Assistance with regular assessments using unmanned aerial vehicles

- Regular inspection flights with unmanned aerial vehicles (photo documentation)

- Project control

- Overall project control across all 3 construction stages

- Environmental & Geoservices

- Occupational health and safety coordination

- Measuring the track geometry

- Use of 3D scanners prompt clearance checks

- Environmental service

- Pollutant analysis of the existing coating

- Geotechnical monitoring

- Installation and operation of a wind and snow measuring system